The WHRS100 Waste Heat Recovery System of ContiOcean was officially delivered and put into actual vessel operation one year ago. With a rated power output of 80kW, the system has evolved from the anxious anticipation of its maiden sea trial to the steady operation that has navigated through all seasons and across latitudes. This past year is not merely a marker of time, but a testament to the depth of our quality craftsmanship. Boasting exceptional stability and safety, the ContiOcean Waste Heat Recovery System has delivered an outstanding performance report featuring consistent high power generation and zero safety incidents. It has brought tangible energy-saving benefits to shipowners and provided the "ContiOcean Solution" for advancing energy conservation and emission reduction in the shipping industry.

Rock-Solid: Stable Performance Amidst Volatile Climates and Sea Conditions

Over the past year, the vessel has sailed across multiple climatic zones, exposing the waste heat recovery system to harsh winds and waves, and drastic fluctuations in seawater temperature. Faced with such complex operating conditions, ContiOcean WHRS has exhibited extraordinary adaptability to varying working conditions.

-

Intelligent Control for Steady Operation: Leveraging independently developed core algorithms and control logic, the system monitors environmental and operational status in real time and automatically adjusts parameters. Regardless of changes in external operating conditions, the unit always operates in a high-efficiency range, maintaining a stable power generation output.

-

Multi-Layer Protection for Safe Operation: The system’s safety protection logic has stood the test of actual vessel operation in numerous severe sea conditions. Thanks to its redundant design and comprehensive safety mechanisms, the equipment maintains stable operation even in turbulent and vibrating marine environments, and achieves seamless coordination with the vessel’s main engine system.

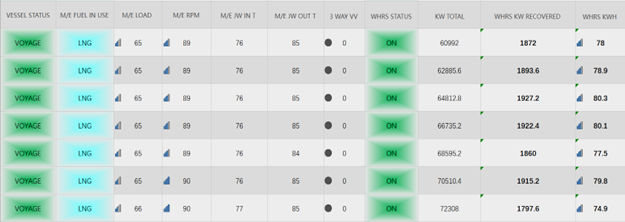

Actual vessel operation data shows that when the operating conditions meet the design criteria, the WHRS100 can continuously and stably deliver its rated power of 80kW.

Figure 1: Daily power generation data recorded bythe Chief Engineer

Service First: More Than Just Responsiveness, It’s Whole-Hearted Guardianship

Vessels sail across the globe, and our services must extend in tandem. To this end, ContiOcean has established a global service system of "Proactive Prevention & Ultra-Fast Response" specifically for the WHRS.

Over the past year, ContiOcean technical team has kept a constant watch on the system’s operational status. Whether the vessel is berthed at domestic ports or sailing on the high seas, ContiOcean support team remains on call 24/7. Every technical inquiry from the vessel receives a timely response, and the team stands ready at all times to meet every onboard service request.

In July 2025, an abnormal alarm was observed in the control system during the vessel’s navigation. Though the alarm did not impact the system’s normal operation, to ensure the absolute safety of the system, ContiOcean WHRS team immediately conducted an internal technical assessment and promptly dispatched engineers to South Korea. The engineers boarded the vessel for maintenance the moment it berthed, and ultimately eliminated the potential abnormal risks smoothly. This was more than just a technical service—it was the fulfillment of our safety commitment to customers.

Figure 2: ContiOcean engineers conducting technical exchanges with theChief Engineer on the waste heat recovery system

Continuous Evolution: Iterating from "Qualified" to "Excellent"

Delivery is not the end, but the starting point for continuous optimization. ContiOcean technical team has remained highly perceptive to the personalized demands emerging from actual vessel operation and the minor operating condition deviations encountered during the initial running-in period.

By analyzing actual vessel operation data and gathering on-site feedback, ContiOcean technical team has identified multiple potential optimization areas. Though these minor details did not affect the overall operation of the system, the team took the initiative to upgrade the control logic and optimize intelligent functions in pursuit of the equipment’s superior performance, further enhancing the system’s reliability and operational experience.

Currently, ContiOcean has launched the MARK Ⅱ version of Waste Heat Recovery System, which has achieved an all-round upgrade in terms of safety, stability and intelligence. Relying on proven technological accumulation and engineering practice, ContiOcean technical team has expanded the product models of the waste heat recovery system to WHRS100/150/200/250/300. These models can accurately match the application requirements of various vessel types, providing customers with more comprehensive, flexible and practical solutions tailored to actual ship operation.

On this basis, the professional experimental platform for next-generation high-power waste heat recovery technology developed by ContiOcean is currently in the design phase. This platform will provide critical test support for system performance verification, control logic optimization and energy efficiency breakthroughs, further consolidate core technological reserves, and lay a solid foundation for the sustained upgrading and technological leadership of the marine waste heat recovery sector.

365 Days: A Milestone, and a New Starting Point